OUR PROFESSION

– Imagine, develop, and operate innovative sorting and separation processes.

– Extract non-ferrous metals from waste generated by incinerated household waste.

– Produce the optimal concentration of these metals for valorization.

OUR SOURCE

The purchase of this incinerated raw material composed of ashes, glass, mineral fractions, and ferrous and non-ferrous metals, ‘sludge’ unusable in its current state.

OUR APPROACH

The ecological dry process.

Developed internally by Récyf, it separates components in about fifteen steps.

Up to 99.9% of the materials entering our facility are thus valorized.

AND SO MUCH MORE…

Retrofitting, transforming, or diverting from their primary functions.

Several solutions are possible. It is also possible to decompose, i.e., separate the different constituent materials to make each one reusable.

For some objects, these methods may not work.

To avoid landfilling, incineration proves very relevant. This process has the advantage of dual valorization: energy and sorting by materials.

It is this latter device that Récyf has focused on: household waste that has been incinerated. Incineration reduces the waste mass by about 75%. It provides heat that can supply urban networks with hot water or turn a turbine to produce electricity. The waste becomes ‘clean fuel.’

The residue of incineration is essentially composed of glass, rocks, ash, and metals. Récyf retrieves it to process non-ferrous metals present.

The uniqueness of waste lies in its notable differences: shape, density, size, color… The complexity of our profession lies in treating and sorting them by materials and granulometries so that they become homogeneous enrichments.

It is our strength to be able to include all these constraints, both in our research methods and in the regulatory framework.

The recognized efficiency of our ‘in-house’ processes allows us to capture metal particles as small as a few microns.

99.9% of the materials entering our facility are valorized.

This result has a positive impact on the supply chain of our deposit suppliers.

It is a replica of the natural history of the repulsive caterpillar transforming into an elegant butterfly.

At Récyf, waste becomes a noble material.

The finished product, generated by our processes, becomes compatible with multiple applications and transformations. Its stability and regularity represent a reliable guarantee for our clients. Logically, this new material will be qualified through the creation of a Récyf standard. We have already initiated studies for the development of a range of objects to be produced internally, directly from our production lines. Several downstream actions, assisted by the best technologies, will authorize these mutations.

Our operation? Questioning our processes every day to achieve ever-improved finesse and concentration of the materials entrusted to us.

Through this approach, we have a firm intention to reaffirm the concept of Recycled/Recyclable. Our philosophy, like our industrial system, fully aligns with the active pursuit of a circular economy.

INVESTING IN RESEARCH AND DEVELOPMENT FOR FUTURE OPPORTUNITIES

POT XXL

Designed by the Product Engineering Agency Piopio in 2022

EVOLVING BENCH

Designed by Mathilde Baure, a student at the City of Design in Saint-Étienne in 2022

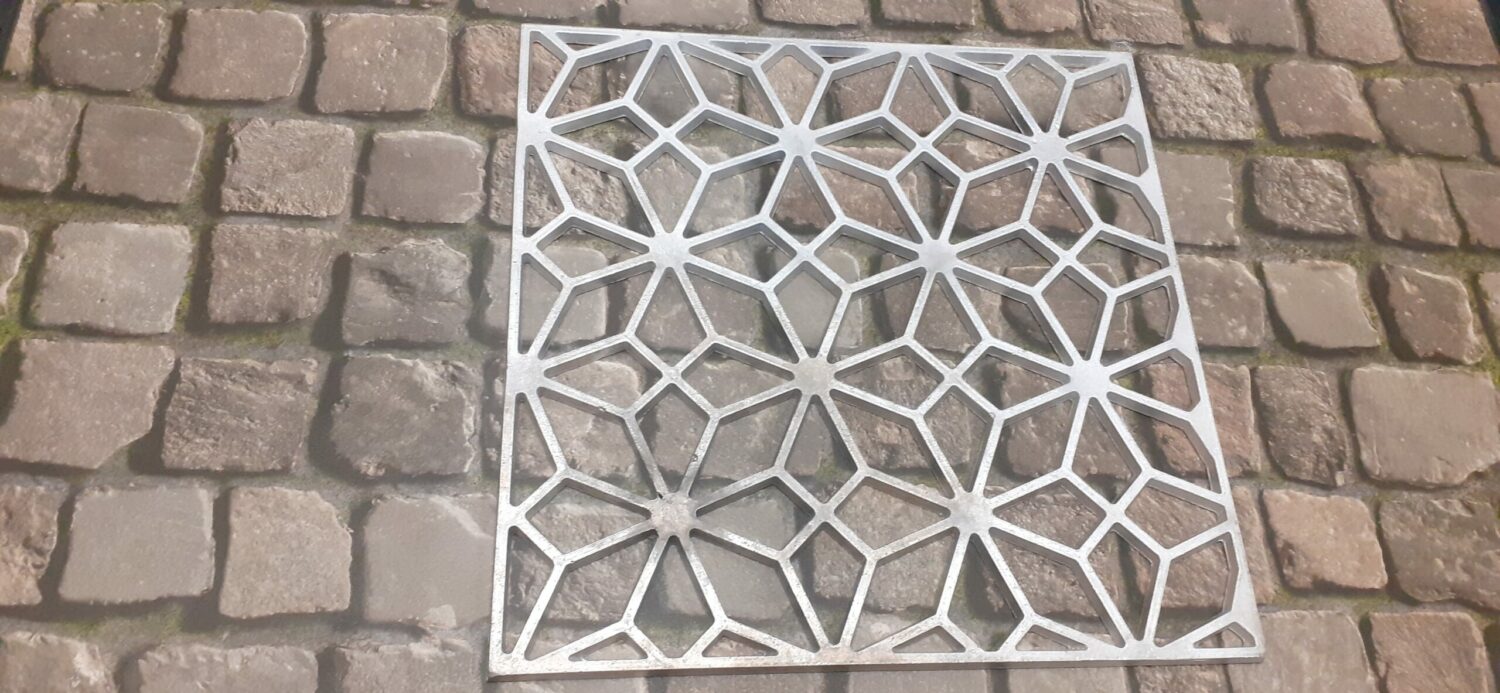

TREE GRILLE

Designed by our Engineering and Methods Office in 2023

WINDSCREEN / VENTILATED CLADDING

Designed by the Engineering Office and the team from our Methods Service in 2023

MULTICOLORED FLOWER POTS

Designed by the Engineering Office and the team from our Methods Service in 2022

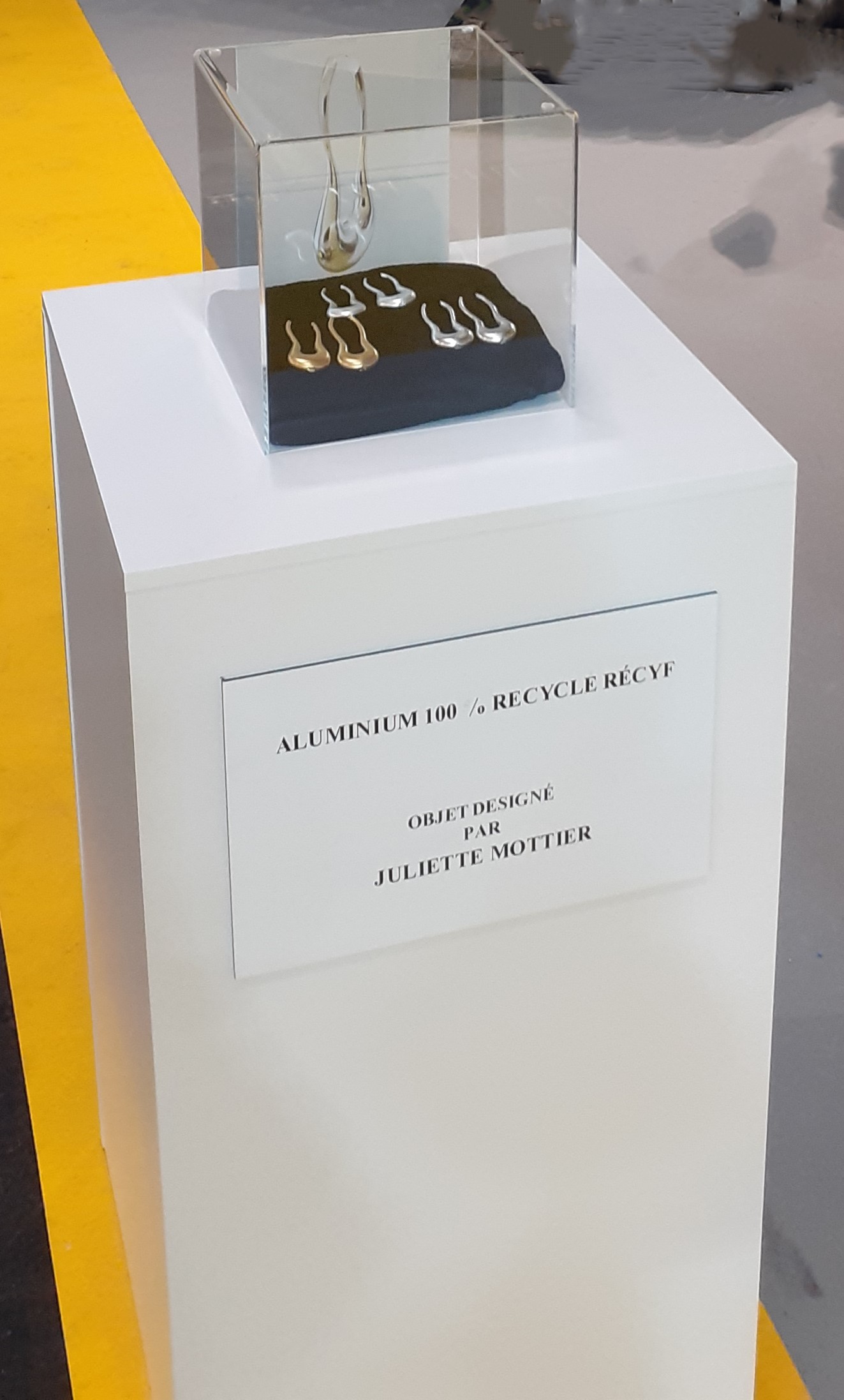

EARRINGS

Designed by Juliette Mottier, a student at the City of Design in Saint-Étienne in 2022